Anthem Advantage

- Home

- »

- Anthem Advantage

Anthem's end-to-end business model across the drug life cycle

CRDMO

Technology platforms across discovery to commercialization phase

CHEMICAL SYNTHESIS

(Small Molecules)

Chemistry, integrated drug discovery

Custom synthesis, GmP manufacturing: mg to MTs

BIOLOGICS

(Large Molecules)

Therapeutic antibody, enzymes & proteins, discovery & engineering

Biologics and fermentation manufacturing

SPECIALTY INGREDIENTS

Health & Nutrition focused

Innovation Driven & Technology Focused

THE ANTHEM DIFFERENCE

1

One of the few Indian companies focused on large molecules

2

One of the leading enzymes solutions providers in India catering to global markets

3

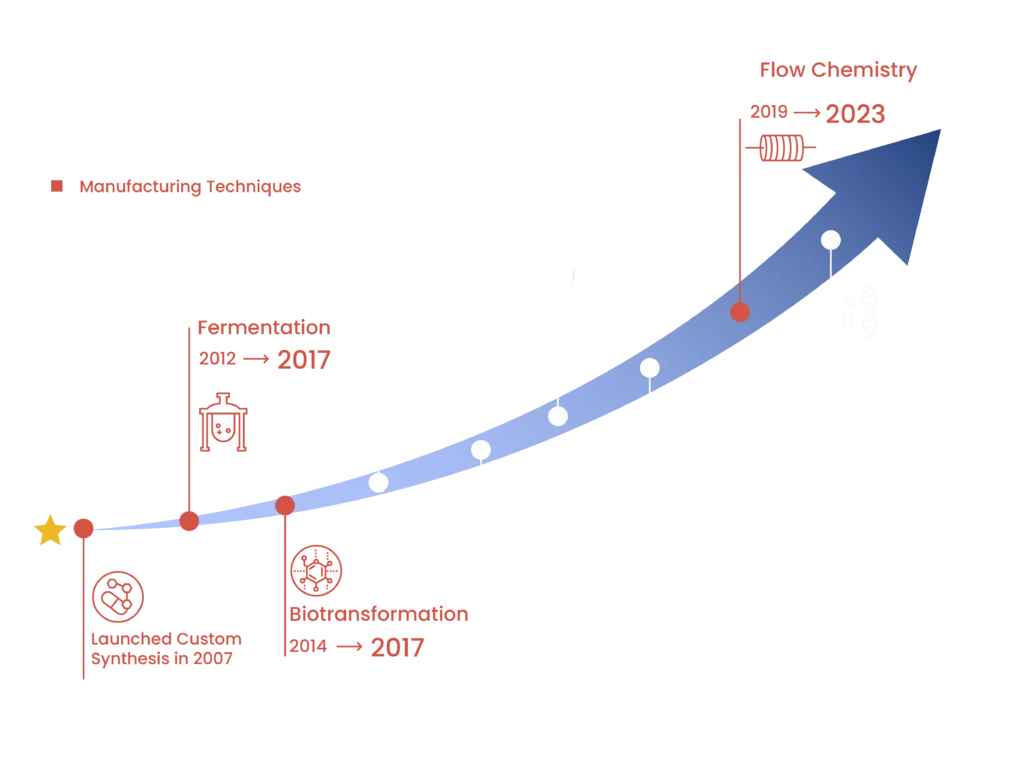

Among the pioneers in India to introduce biotransformation and flow chemistry

4

Green chemistry: Biocatalysis, flow chemistry, pincer catalysts, micellar chemistry

5

Advanced capabilities in high-potency compounds

Anthem’s Expertise spans across the Entire Spectrum of Small to Large Molecules

Anthem’s Platform Technologies

CRDMO Capabilities

Small Molecules

Small Molecule API / Intermediate Manufacturing

Oligonucleotide / Peptide / RNAi

Solid phase production of Peptides / Oligonucleotide

Small Protein

Fragment Antibody

Recombinant Protein Production

Green Chemistry

1

Anthem has developed and scaled up chemical process using flow technology

2

The team with 20+ years’ experience successfully transferred several batch to flow process which possessed safety hazards, batch variability & effluent load

3

Benefits of Flow chemistry over conventional chemistry: Safety, scalability, consistency, reduction in solvent & synthesis cycle time

1

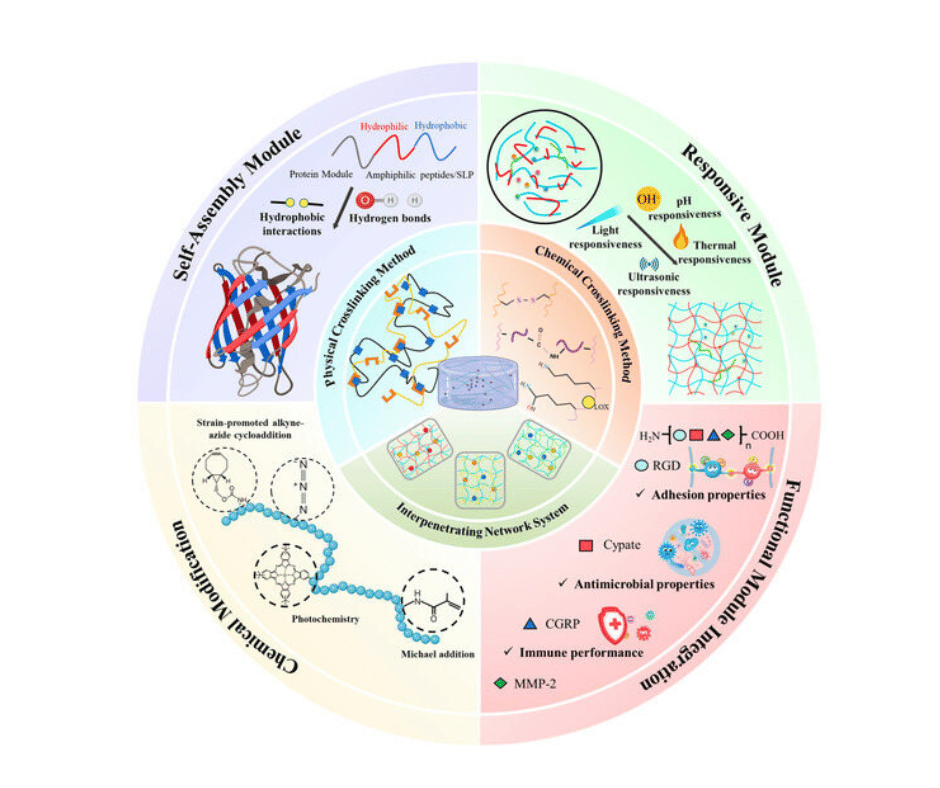

Anthem uses proprietary technology to produce biodegradable and recyclable surfactants with minimal solvent

2

Affords greener solution of conducting synthesis in water, with better kinetics of chemical reaction & cleaner reaction profile

1

Anthem has adopted green chemistry utilizing enzymes from living sources to speed up chemical reaction, thus providing chirally pure compounds with lesser impact on environment

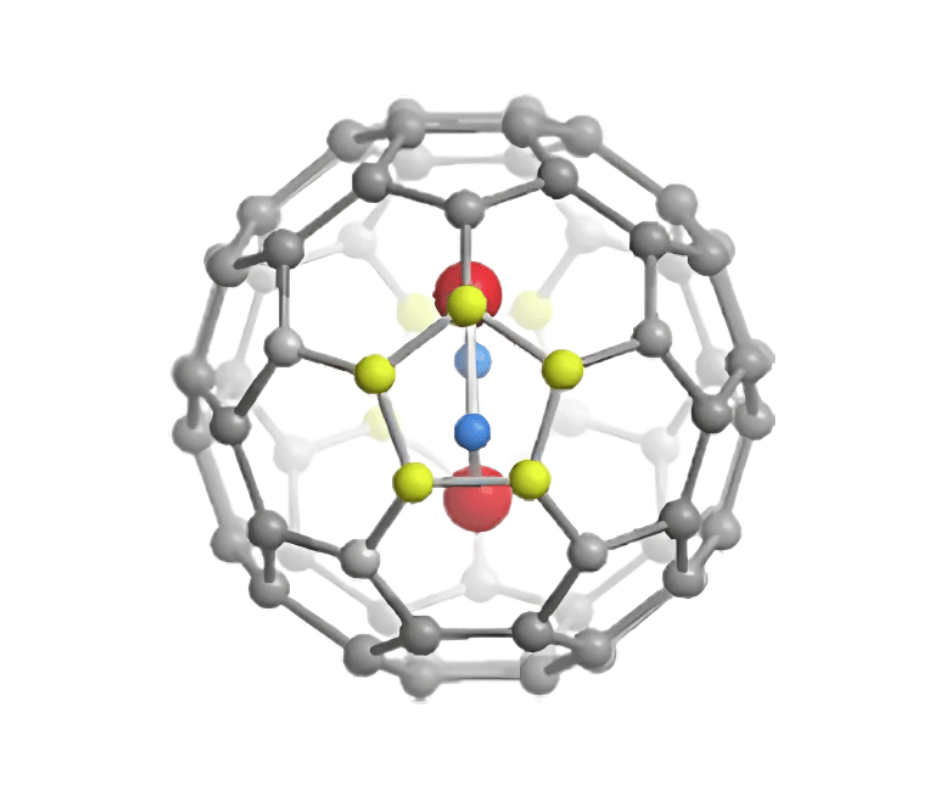

1

Anthem uses proprietary and commercially available Pincer complex

2

Better alternative to hazardous pyrophoric metal hydrides

3

Ease of isolation avoiding excessive solid waste generation

State-of-the-Art Automated Manufacturing Infrastructure, across 3 units in Bangalore, India

Unit I: Bommasandra

Established 2007 | 5 Acres | USFDA (2013, 2017, 2019, 2025) | ANVISA | PMDA

Unit II: Harohalli

Established 2016 | 15 Acres | USFDA (2023, 2024) | ANVISA | PMDA | TGA

Unit III: Neo Anthem

Established 2024 | 8 Acres | An Anthem Subsidiary