Cell Line Development

- Home

- »

- Cell Line Development

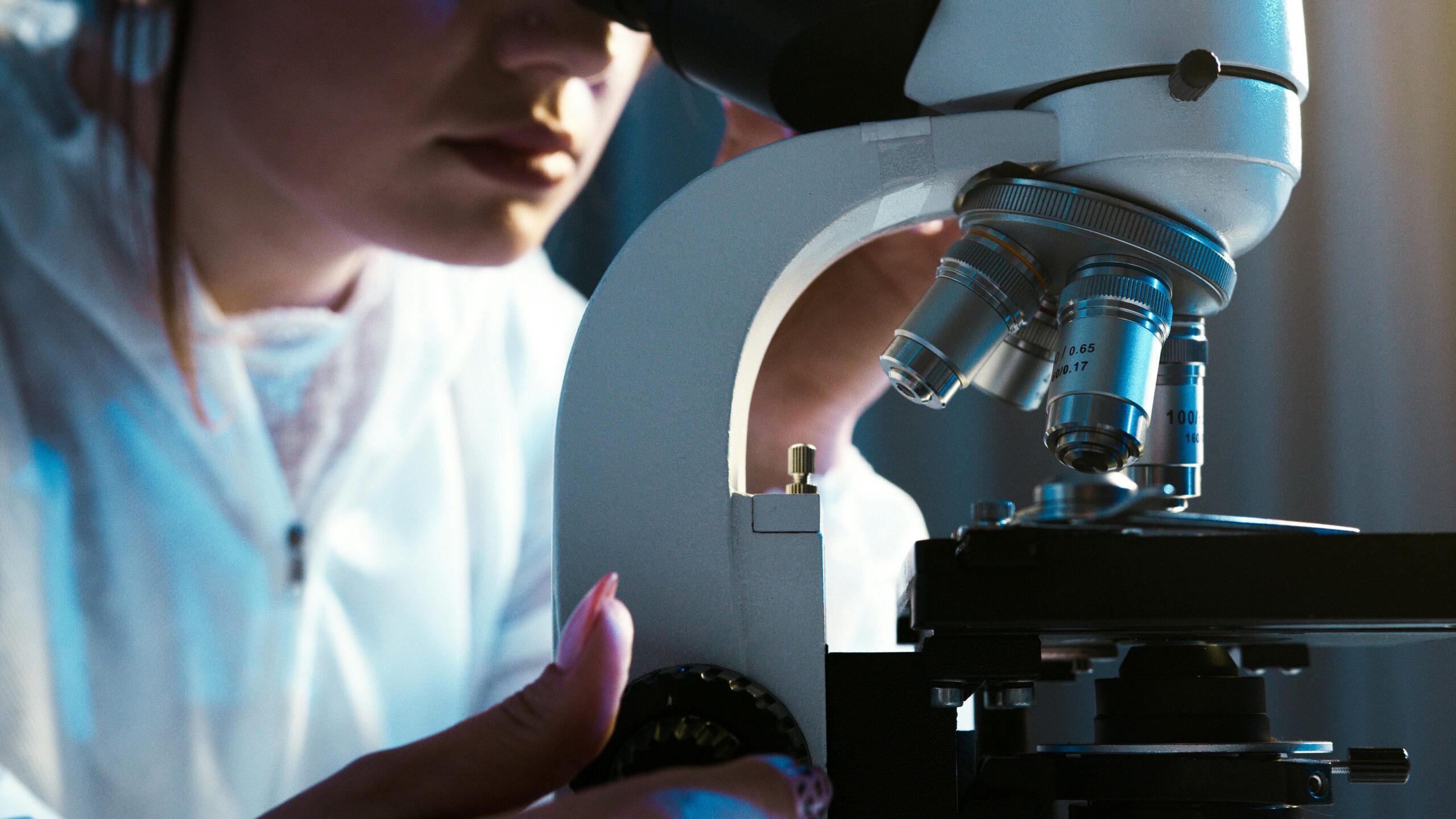

Foundation for Efficient and Scalable Biologics Production

Cell line development (CLD) is a critical step in the development of biologics, shaping the efficiency, yield and quality of therapeutic proteins and antibodies.

Mammalian Cell Lines

Microbial Cell Lines

Key Stages in Cell Line Development

Gene Integration & Transfection

Stable incorporation of the gene of interest into the host genome using random or targeted integration methods, including transposase technology.

Screening & Selection

High-throughput screening identifies clones with optimal expression levels, growth characteristics and product quality.

Single-Cell Cloning & Stability Assessment

Ensuring monoclonality through advanced cloning techniques and verifying genetic and expression stability over multiple passages to guarantee consistent manufacturing performance.

Design of Experiments (DoE)

Genetic Engineering Tools

Single-Cell Sorting & Imaging

Quality, Scalability & Regulatory Compliance

1

Monoclonality Assurance

Adherence to regulatory expectations by establishing and documenting monoclonality to ensure product consistency.

2

Scale-Up Strategies

Seamless transition from lab-scale cultures to commercial bioreactors (up to 30,000 L), maintaining product quality and process robustness.

3

Regulatory Support

Comprehensive documentation and quality control to support IND, BLA and global regulatory submissions.